Advanced Sugar Mill Tech by Euroindustriel - Innovation Focus

In the realm of sugar production, technological advancements have significantly revolutionized the industry. The integration of cutting-edge machinery and sophisticated equipment has been pivotal in enhancing efficiency, improving yield quality, and ensuring sustainability in sugar mills worldwide. This evolution is a response to the growing demands of a market that continually seeks higher standards in both production and environmental conservation.

Enter Euroindustriel, a key player in this technological transformation. With a keen understanding of the sugar industry’s unique requirements, Euroindustriel has positioned itself as a provider of innovative solutions specifically designed for sugar processing. Their range of products, including Trash Plates, Rollers, Hammer Tips, Conveyor Belts and Chains, Boiler Tubes, and Juice Heater Tubes, represents the pinnacle of industry-specific engineering. Each piece of equipment is crafted to meet the highest standards of efficiency and durability, underscoring Euroindustriel’s commitment to advancing the sugar milling process through state-of-the-art technology. This introduction sets the stage for a detailed exploration of Euroindustriel’s comprehensive suite of products, each playing a critical role in modernizing sugar mills and driving them towards a future of greater productivity and sustainability.

The Importance of Advanced Equipment in Sugar Mills

The efficiency and reliability of equipment in sugar mills are critical factors that directly impact the overall productivity and profitability of the sugar processing industry. Advanced machinery and technology play a crucial role in optimizing production processes. They do this by ensuring precise control over various stages of sugar processing, from cane handling to juice extraction, and crystallization. Technological advancements not only enhance the efficiency of these processes but also significantly reduce downtime. This is vital in an industry where time-sensitive operations are a norm. The deployment of cutting-edge equipment, therefore, is not just a matter of upgrading machinery but is integral to maintaining a competitive edge in the market. By minimizing operational delays and maximizing output quality, technology becomes the cornerstone of a successful and sustainable sugar milling operation.

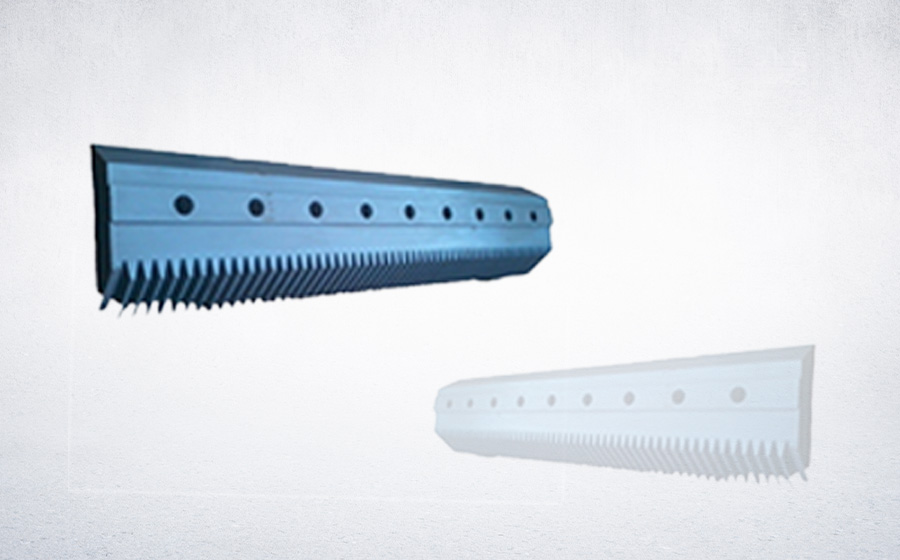

Trash Plates

Trash plates in sugar milling are crucial components that play a vital role in the cane crushing process. They are positioned in the sugar mills to assist in the efficient extraction of juice from the sugarcane. Trash plates work by providing a scraping action against the rollers, helping to extract more juice and reducing the amount of bagasse moisture. This results in a more efficient milling process.

Euroindustriel’s approach to trash plates focuses on innovative design, aimed at enhancing milling efficiency. Their trash plates are engineered to offer improved durability and optimal performance, contributing to the overall effectiveness and efficiency of the sugar milling process. The design enhancements by Euroindustriel ensure that the mills run smoother and more effectively, ultimately leading to higher juice extraction rates and improved productivity in sugar production.

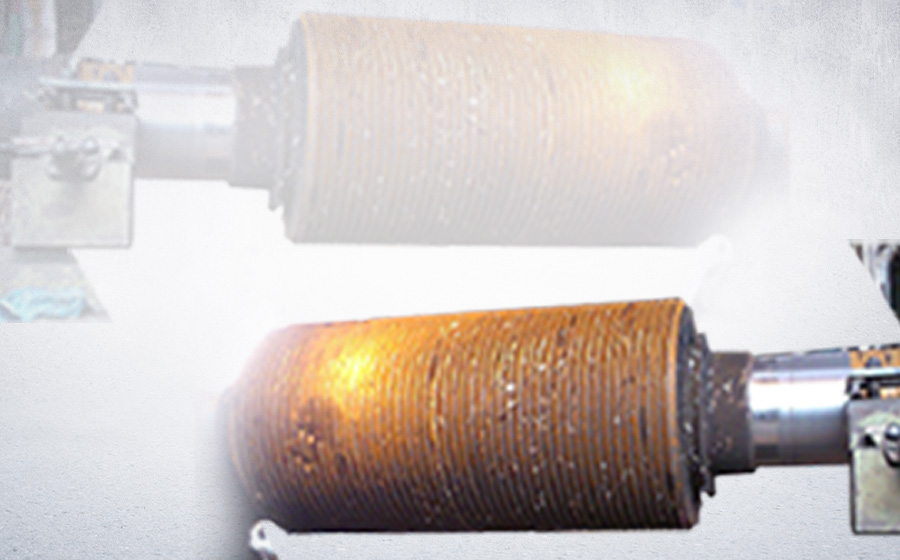

Rollers

Rollers in sugar mills are fundamental to the cane crushing process, playing a pivotal role in the extraction of juice from sugarcane. They are designed to effectively crush the cane and extract as much juice as possible. The efficiency of the rollers directly impacts the quantity and quality of the juice extracted, which in turn affects the overall production of sugar.

Euroindustriel’s rollers are engineered to offer superior performance in several key aspects:

- Optimized Design: Their rollers are designed to maximize juice extraction while minimizing the energy required for crushing.

- Durability: Made with robust materials, these rollers withstand the rigorous demands of continuous operation in sugar mills.

- Enhanced Surface Texture: The surface texture of Euroindustriel’s rollers is optimized for better grip and more effective crushing of the sugarcane.

- Reduced Maintenance: Their design reduces the frequency of maintenance, thereby minimizing downtime and ensuring consistent operation.

By incorporating these advanced features, Euroindustriel’s rollers help sugar mills achieve higher efficiency, better juice quality, and increased overall productivity.

Hammer Tips

Hammer tips are used in the initial stages of sugar processing, primarily for shredding cane before it is sent for milling. The shredding process is crucial as it prepares the cane for efficient juice extraction, a vital step in sugar production.

Euroindustriel’s hammer tips are designed to be both durable and efficient, key features in maintaining continuous and effective operation within sugar mills:

- Enhanced Durability: Made from robust materials, these hammer tips withstand the rigorous and abrasive nature of cane shredding.

- Optimal Efficiency: Their design ensures effective shredding, which facilitates better juice extraction in subsequent milling stages.

By integrating these high-quality hammer tips into their equipment, Euroindustriel ensures that sugar mills operate with greater efficiency and reduced downtime, directly contributing to the overall productivity and effectiveness of the sugar processing operation.

Conveyor Belts and Chains

In sugar mills, conveyor belts and chains are essential for efficiently moving raw materials and processed products throughout the facility. They play a critical role in transporting sugarcane, bagasse, and sugar from one part of the mill to another, ensuring a smooth and continuous flow in the production process.

Euroindustriel’s conveyor solutions offer several features that ensure smooth and efficient operation:

- Durability: Built to withstand the demanding environment of sugar mills.

- Efficiency: Designed for optimal material transfer, reducing spillage and blockages.

- Customization: Able to be tailored to specific needs and configurations of different mills.

- Maintenance-friendly: Easy to maintain, ensuring minimal downtime.

These characteristics make Euroindustriel’s conveyor belts and chains a reliable choice for sugar mills, enhancing overall operational efficiency.

Boiler Tubes

Boiler tubes in sugar mills are integral for generating the steam required in various processes, including the evaporation and crystallization stages. These tubes heat the water in the boilers, producing the steam necessary for these processes.

Euroindustriel’s boiler tubes offer significant benefits:

- Energy Efficiency: Optimized to reduce energy consumption, leading to cost savings and environmental benefits.

- High Reliability: Designed to withstand the high-pressure and temperature conditions typical in sugar mills, ensuring consistent performance.

Juice Heater Tubes

Juice heater tubes are crucial in sugar mills for heating the sugar cane juice before it enters the evaporation stage. This heating process is vital for efficient sugar recovery.

Euroindustriel provides juice heater tubes that are:

- Efficient Heat Transfer: Ensuring quick and uniform heating of the juice.

- Durable: Capable of withstanding the corrosive nature of the sugar juice and the thermal stresses of heating operations.

These features of both boiler and juice heater tubes from Euroindustriel play a critical role in enhancing the efficiency and reliability of the sugar milling process.

The heating process in sugar mills, particularly the use of juice heater tubes, is critical for improving sugar quality. Proper heating enhances the clarification process, which is essential for removing impurities from the sugar juice. This step is crucial for producing high-quality sugar.

Euroindustriel’s range of equipment, including boiler tubes and juice heater tubes, is pivotal in enhancing the efficiency and output quality of sugar mills. By incorporating these advanced technologies, Euroindustriel helps sugar mills achieve higher productivity, energy efficiency, and produce superior quality sugar, thereby reinforcing their commitment to innovation and excellence in the sugar industry.

Choosing Euroindustriel for sugar mill equipment offers several benefits:

- Advanced Technology: Their products, from boiler tubes to conveyor systems, embody the latest in industrial innovation.

- Efficiency and Quality: Euroindustriel’s equipment enhances operational efficiency and sugar quality.

- Durability: Designed to withstand the rigorous demands of sugar processing.

- Custom Solutions: Tailored to meet specific industrial needs.

Euroindustriel invites you to explore their full range of products, designed to revolutionize your sugar milling operations. Discover how they can be a part of your journey towards enhanced efficiency and productivity.